Friends, this post is all about me and 6 months of oddly satisfying tinkering……unlike the Franklin restoration which was all consuming for 8 months, the plan with the Airstream was to chip away at things until Christmas, when the serious work of replacing the floor then building the new interior cabinetry would start.

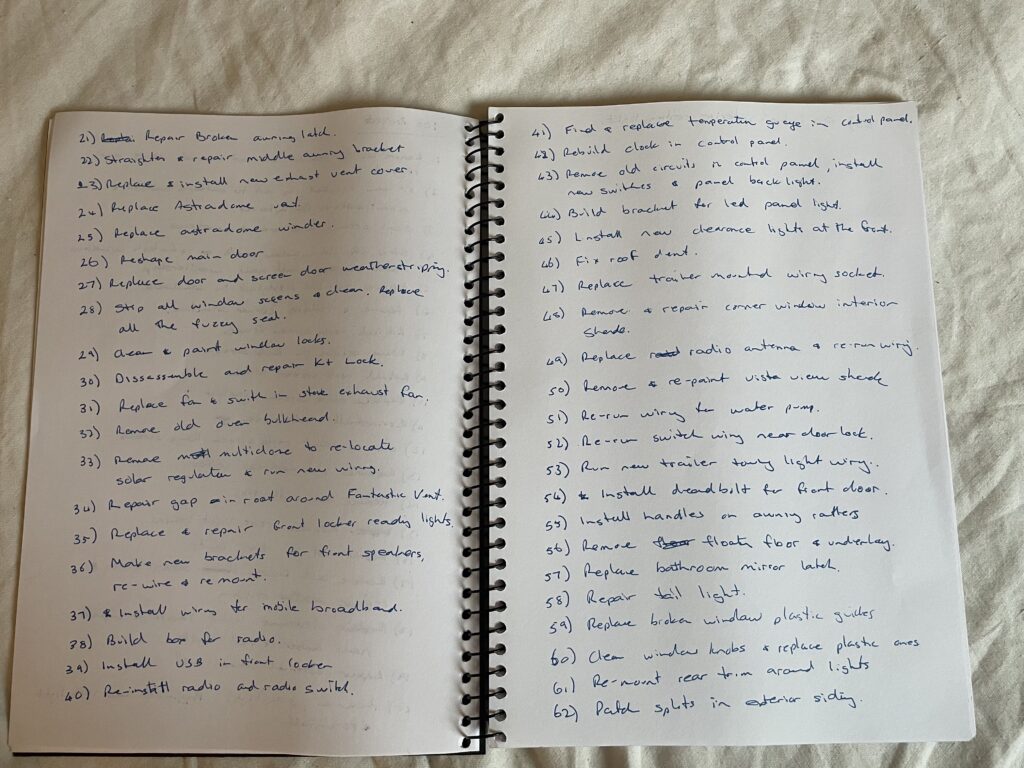

The first job was making her absolutely watertight. But then another 60+ small projects that most people will never notice, but I found oddly satisfying. I made a list for my own edification. Some quite complex, some time consuming, some easy and quick and not really worth a blog post of their own, so here’s a picture of our vintage trailer park in our front yard, and my list of oddly satisfying projects.

Hot tin roof

A weekend on the roof clearing off all the old silicone and sealant around all of the vents and replacing with Sikaflex. Remove all of the vent caps over the exhaust pipes and replace the rubber seals. Sikaflex the joins at risk of leaks.

Solar Prep #1

We’d installed flexible solar panels on the roof on the island, and the regulator in various handy positions in the cabin. Megan was not as enamoured with staring at the display screen and watching the batteries charge as I was unfortunately.

To solve that problem, as well as the longer term plan for the interior, I pulled down the multidome (centre ceiling strip), rerouted the solar panel wiring to the rear bathroom, and temporarily installed the regulator on the wall.

Sounds simple. Two weekends of hard graft.

Video killed the radio star

The old tv aerial was broken and the original cable won’t work with modern televisions – and we watch everything online and streaming in any case.

I built a bracket instead to mount a mobile broadband whip on the tv antenna mount, then fished the cable internally through to the front overhead locker, where we installed a USB port and connection for our mobile broadband hotspot.

At the same time we built a better mount for the radio in the locker, replaced the corroded radio whip antenna and ran a new cable to the radio. We’d already upgraded the old speakers and speaker wiring previously, but build better mounts for the speakers so they would stay in place when on the road.

A room with a view

The windows took two months of weekends on their own. Some glass windows were intact, but needed new seals, the locks needed cleaning and servicing, opening arms cleaning and painting, replacing the plastic slides that hold the windows in their open positions, resealing the glass in its frame on the outside and the frames in the walls.

Cleaning up the screens, replacing the fuzzy seal, installing new midge-proof insect screen.

The rear window and several of the side windows had been broken at various times and replaced with acrylic that had deteriorated over time. Genuine airstream windows are expensive and hard to find. The rear window is flat, so replacing it with tinted acrylic was fairly straightforward.

The side windows are curved – so we replaced these with new 3mm UV stabilised marine grade acrylic and used insect screen spline on the inside edge between the acrylic and the frame to hold it secure – and also to force it to the correct curved shape. This is the same way Airstream secures the acrylic in the rock guard at the front so we knew it would work.

We had the original rock guard frame, so it just needed cleaning, the opening arms needed rebuilding, the catches on the front of the trailer were replaced, new acrylic installed and new seals.

The most complex window job was the broken front curved window. These can’t be rebuilt with acrylic – they need to be replaced. We ordered one from the US, removed the old window frame, and installed the new one using Olympic rivets, which can be ground back to look just like the original bucked rivets.

By December the Airstream was watertight, no leaks and ready to start work in the new year on the floor. My list of jobs completed to that date tapped out at 63….